SUMMARY:

- Reactive Inkjet Printing (RIJ) to build 3D hydrogel structures from poly-s-lysine and gellan gum, optimizing ink properties for precision, stability, and biocompatibility.

- There are several advantages of microdispensing, as it can create complex structures.

- Printed hydrogels can be printed in honeycomb-like topography and supported healthy growth of human corneal epithelial and endothelial cells, indicating strong potential for corneal tissue engineering.

Background

-

Antimicrobial resistance (AMR) is a growing global health threat, especially in regions with limited access to diagnostic infrastructure.

-

Effective treatment of bacterial infections requires pathogen identification and antimicrobial susceptibility testing (AST).

-

Traditional AST methods (e.g., agar plates, broth dilution) are labor-intensive, require refrigeration, and are unsuitable for resource-limited settings.

-

There’s a need for low-cost, easy-to-use, and scalable diagnostic tools that can operate without sophisticated lab infrastructure.

- Here we review the work which was published in this publication

Reasons for Using Inkjet Printing

Microdispensing offers several advantages:

- Microdispensing (specifically inkjet printing) enables precise, reproducible, and scalable deposition of reagents like antibiotics onto diagnostic substrates.

- It allows for controlled concentration gradients essential for MIC (Minimum Inhibitory Concentration) testing.

- Compared to manual methods, microdispensing ensures uniformity, customizability, and high-throughput production, making it ideal for manufacturing ready-to-use (RTU) diagnostic devices.

Approach

Reactive Inkjet Printing involves several key steps:

-

RIJ was used to fabricate 3D hydrogel constructs by alternating layers of poly-s-lysine (peK) and gellan gum (GG).

-

RIJ is a drop-on-demand inkjet technique in which two reactive inks form a solid hydrogel upon contact through ionic bonding.

-

The inks were optimized for rheological properties—viscosity, surface tension, and contact angle—to ensure printability and structural stability.

-

Constructs were printed as flat arrays and porous bitmaps, with varying numbers of passes to control thickness and porosity using spot on spot printing with two heads

The video demonstrates spot-on-spot printing as an example of combining different compounds at a single location:

Utility and Outlook

-

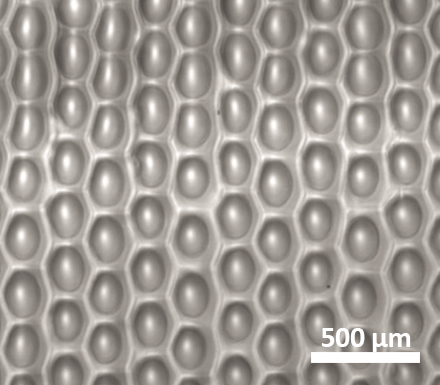

Printed hydrogels exhibited a unique honeycomb-like surface topography, confirmed through both optical and SEM imaging.

-

Cell culture studies showed strong attachment and typical morphology of corneal epithelial and endothelial cells on the printed hydrogels.

-

The work of Katie Blacks group highlights the potential of 3D printing for developing cell culture models and investigating corneal replacements, particularly for conditions such as LSCD and Fuchs dystroph.