Microarrays

get far less media coverage than covid-19, influenza and cancer.

Perhaps because a larger audience can be attracted by problems than by their solutions. Microarrays are perhaps the most significant biotech solution in the field of modern life sciences and are the heart of microdrop Technologies’ life science division.

What is the meaning of microarray, why are microarrays this important and what applications do they fulfill are the topics of this article.

Why are solutions like microarrays essential for life science.

The increasing global health threats from viral diseases and cancer pose huge challenges to medical and life sciences. Antibiotics are useless in these cases. This is because both viruses and cancer penetrate the cells and change their functions from the inside. To simplify, there are two approaches to combating this problem:

- Affected cells are completely eliminated. However, if too many cells are affected, this ends fatally. It is often a race for life and death.

- With modern biotech solutions, it is possible to identify where the damaging potential lies in the cell programming. This can then be specifically shut down. The cell lives on.

There is probably widespread agreement that it is healthier and more desirable to let the cells live rather than let them die. This is where microarrays come in. But let´s look at this in a turn by turn fashion.

Heterogenous milieus are a fundamental bioscience challenge

When it comes to understanding viruses, cancer cells or DNA bioscientific terms, a fundamental challenge, the common denominator, becomes apparent in biochemical analysis: they are highly heterogeneous. It is easier to conduct research on bioscientific environment if it is relatively constant, i.e. homogeneous.

But if the sample composition is irregular, heterogeneous, it quickly becomes very complex. How can such physiologically and biologically heterogeneous environments be systematically studied scientifically? The answer is: with the help of microarrays.

Microarrays can be used to generate large amounts of data on the reaction of heterogenous cells, cell components or DNA.

The valuable huge amounts of data that are available and can be provided thanks to the microarrays can be systematically compiled in globally usable databases and used as a scientific reference for the development of drugs and therapeutic procedures. Microarrays are the central solution for building databases that can be used in the life sciences.

The use of microarrays combines several advantages for the construction of databases and the execution of the associated processes:

- Simplified workflows

- High throughput platform

- uncomplicated transfer of results

- simple scalability

Microarrays enable automated analysis of heterogeneous sample material

From the above-mentioned advantages in the use of microarrays generate, a general major advantage arises: automatability.

Automation is economically and scientifically highly attractive. Because processes that can be automated are fast, reproducible and efficient.

And in case of the microarrays individual results can still be obtained for heterogeneous sample material.

This combination is a bioscientific sensation. If not to say a biotechnological revolution, similarly revolutionary as the steam engine and the assembly line were at the time of the industrial revolution. Microarrays are the assembly line of modern bioscience.

They are advancing life science in an extraordinarily significant ways.

They are the assembly line of modern bioscience.

Microarrays are a revolutionary sensation.

The use of microarrays enables more sustainable production and accelerates research development

With the use of microarrays comes miniaturization. Microarrays can process extremely small samples. This brings enormous sustainability advantages, because thanks to the microarrays, resources are conserved in many ways. Thus, the use of microarrays can save both time and money. In addition, the use of microarrays requires significantly smaller quantities of sample material. This not only saves financial resources, but also reduces the burden on the sample donor.

And the extremely space-saving property of microarrays also saves precious resources. The examination area on the substrate for the microarray is so tiny that it can only be processed by a technical dispensing system. This high-precision dispensing system replaces the parallel use of several machines. Simply because fewer machines are needed, the acquisition budget for machines is also spared.

If fewer machines are in use, fewer staff are needed to operate them. This in turn gives financial space, which allows human capacities to be focused on the actual research activity. And this is exactly what makes the research work efficient. In addition, the analysis results can be easily forwarded to a computer in the form of electrical signals, where they can then be evaluated.

Smart researchers and efficient tools are the two supporting pillars for research progress

Researchers want to research and investigate. And that is exactly what they should be able to focus on.

Microarrays are a first tool to make exactly that possible. But microarrays can only play out their advantages if they work hand in hand with high-precision dispensing systems. This is where the technical dispensing systems from microdrop Technologies enter the playing field.

The micro dispensing systems combine years of experience and developments in technology in connection with minimal dispensing units and their challenges, so that the user can fully focus on his investigations.

Microarrays play an essentially important role

in life science work, research and development. Microarrays score particularly well in the analysis of heterogeneous sample material and enable the rapid systematic development of large databases. In addition, microarrays are also very attractive from an economic point of view and conserve resources.

What are microarrays

and how do they work?

Microarrays are a method of high throughput screening.

As the name High Throughput suggests, microarrays are a method that produces an enormous amount of data. The samples to be examined are usually arranged in a rectangular basic pattern. The pattern forms the framework for a point-by-point dosage of the sample material. Due to the initially simple basic structure, the microarray can be easily automated. The basic pattern of rectangular frames is “scanned” automatically and ensures highly precise accuracy in a very small space. In addition, scalability and a high throughput of the resulting data go hand in hand with the ability to automate.

The sample material is dispensed onto a carrier material in the smallest possible dimensions (up to a few pl). the carrier material is generally referred to as a substrate. Several of the rectangular microarrays can be arranged on one substrate. This brings with it an amazing and unprecedented flexibility and analytical reliability that makes this method so unique and revolutionary.

The potential of microarrays is therefore to provide a precise view over very heterogeneous areas and thus reduce uncertainty and be able to initiate targeted responses. In this way, the development of vaccines or the drug treatment of seriously ill patients can be initiated quickly and easily.

The generation of microarrays brings with it several challenges

When generating microarrays, the user is basically confronted with a multitude of challenges. It should be noted that these challenges can be easily overcome with the right technical tools.

Three of the biggest challenges generating microarrays at a minimal room are the following:

- Tiny drops merge easily. This must be prevented.

- Ensure prefect drop formation in a reliable and predictable manner (automation).

- Select a suitable substrate

The three biggest challenges in

creating microarrays in minimal space are:

- Microarray-Challenge 1:

to create the smallest possible droplets - Microarray-Challenge 2:

to ensure perfect droplet formation - Microarray-Challenge 3:

suitable substrate

Microarray-Challenge 1: to create the smallest possible droplets

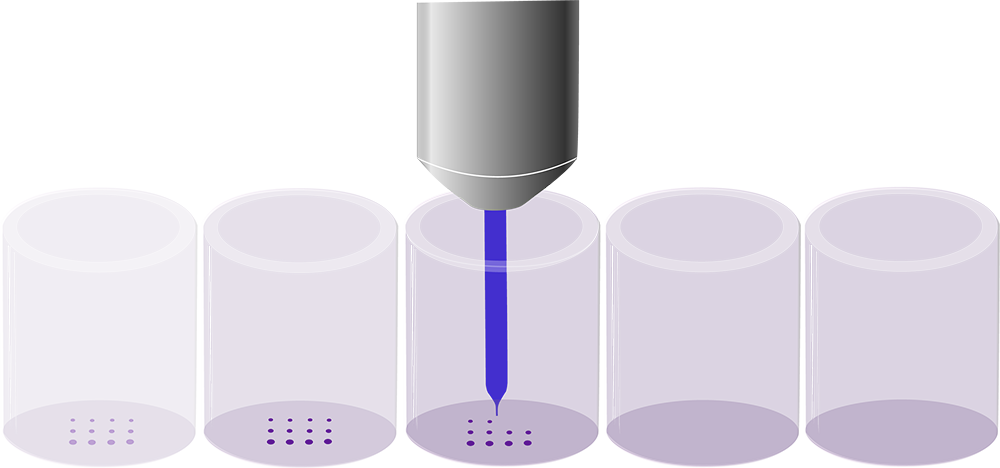

By nature, droplets tend to merge with others to form larger droplets.

This natural property of droplets to merge with other droplets to form a larger droplet is a central and success-deciding challenge in the generation of microarrays. Anyone who has ever tried to create the smallest possible water droplets by hand is probably familiar with the phenomenon that water droplets can be enlarged more easily than they can be reduced. It even seems impossible to go below a certain droplet size.

However, to create optimal microarrays, it is critical to make the best use of the minimum space available, while absolutely preventing individual droplets from merging. The liquids must be deposited onto the substrate with the highest precision and absolute reliability. The pendant drop, which results from the relationship between the surface tension and gravity, must therefore necessarily be broken. It would take up too much of the available space and merging with each other would be very likely. The controlled high acceleration inside the liquid results in dynamic forces that are greater than the surface tension. As a result, the droplet very quickly breaks away from the nozzle and remains at the desired small size. The droplets in the lower picoliter range are so sensitive that only machines and the finest sensor technology can ensure consistent precision quality. In the automated technology environment, the actual dispensing unit has an enormous influence on the process and the drop quality.

A pipette is usually used in the dispensing unit. This pipette plays a decisive role for an optimal dispensing result and perfect droplet formation.

microdrop solution:

microdrop Technologies is specialized in creating extremely small droplets very precisely and reliably. It requires expertise and experience in dealing with droplet formation and the properties of the materials used. To ensure maximum reliability and precision in drop size control in the picoliter range, automation is essential. This is because such tiny droplets cannot be produced reliably and precisely reproducibly by hand under any circumstances. Precision and safety in droplet size can only be guaranteed by automating the work processes, specifically by using specialized machines, dispensing units and pipettes.

Microarray challenge 2: to ensure perfect droplet formation in a reliable and predictable way.

Satellite formation must be monitored

In addition to the challenge with the tiny water droplets merging, there is another challenge with dispensing tiny amounts of liquid: the phenomenon of satellite formation. When handling tiny droplets, such as those required for microarrays, unwanted satellite formation when they hit the substrate can torpedo the entire research effort. Satellites are also droplets that form alongside the desired droplets during dispensing. Again, satellites are much smaller than the desired droplets. Thus, when a droplet with a diameter of about 60 µm is dosed, satellites with a diameter of less than 5 µm can be formed. This is a diameter of only one-twelfth of the actual desired droplet size. Although satellites are much smaller than the actual droplet, they can have a tremendous impact on the dispensed microarray once they hit the substrate. Satellites can spread spray-like onto the substrate at unwanted locations. The result is a contamination of a wider area around the spot where the main drop is hitting the substrate. In this case, the desired results are distorted to such an extent that they become unusable.

microdrop solution:

With its specially manufactured and optimized pipettes, microdrop Technologies offers the perfect option for dispensing different liquids. In combination with an integrated monitoring unit, this is the solution to master the challenge of satellite formation and to perfectly control the dispensing result already in the droplet formation.

A special advantage: the pipette from microdrop Technologies is reusable. It can be cleaned and can therefore be used for various dosing tasks and liquids. This special feature alone makes the pipette from microdrop Technologies an attractive alternative to conventional pipettes: sustainable and cost-effective.

Microarray challenge 3: suitable substrate

The perfect microarray

not only requires the perfect drop, but the decision for the optimal substrate is also equally crucial.

An additional point to consider when creating microarrays is the choice of the right substrate. The perfect formation of the droplet is the first step towards the perfect dispensing result, but just because you can create a perfect droplet does not mean that the result will also be created perfectly and as expected. Whether a drop runs also depends on the properties of the substrate chosen. The properties of the material. Thus, the properties of the material, but also the nature of the surface play a decisive role. A frequently chosen material for the application of microarrays are slides made of borosilicate glass. It can happen that the dispensing of a liquid does not produce the desired results on the substrate. Then a suitable substrate alternative is needed quickly.

Solution by microdrop:

with its systems and years of experience in the field of microdispensing, microdrop Technologies offers the optimum technical support. The challenge of substrate suitability can be mastered in the shortest possible time. Thus, the focus can be directed back to the actual research at an early stage.

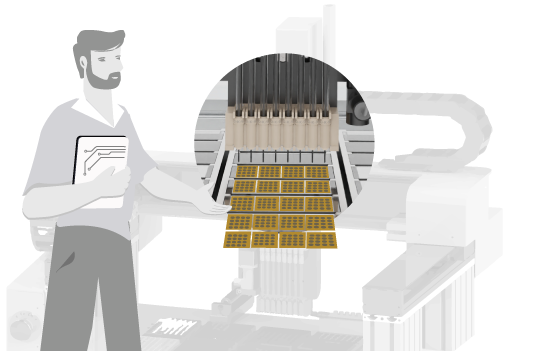

The Autodrop Ganty II system from microdrop Technologies ...

...integrates various solutions to meet the challenges of microarray generation quickly and easily

The experience and knowledge gained in dealing with the above-mentioned challenges have led to the development of the Autodrop Gantry II system. The solutions are bundled in this technical system. The Autodrop Gantry II system represents the optimal technical system in the generation of microarrays. It combines technical developments with years of experience and know-how in handling microarrays. The stable and individual adaptable design integrates the custom-made Autodrop pipette so that optimal droplet formation can take place. A variety of substrates can be positioned in the system´s working space. In this context, the system can be individually adapted to the required number of substrates.

Integrated monitoring unit...

with optical control towards the perfect droplet.

An optical monitoring unit is integrated with which the drop formation can be observed and controlled at different points in time.

Using the software supplied, the parameters (such as frequency, voltage or pulse length) for piezo-based dispensing can be adjusted as desired so that the optimum drop can be produced at any time.

Expansion and customization options for optimal individualization, flexibility and sustainability.

An optional cleaning station allows easy cleaning and fluid changes during the microarray generation process.

Various, optionally selectable positioning units enable the precise positioning of substrates in the workspace, resulting in an overall stable homogeneous system that ensures simple, automated processes and prevents malfunctions.

Various functions within the software allow the necessary flexibility in creating the desired dispensing patterns. We will be happy to advise you on which is the best option for your application.

It all depends on the right support. We advise you right from the beginning.

We also support you throughout the discovery phase and discuss the best options for your applications and budget. Among other things, we offer so-called dispensing test for this purpose, in which our team of experts examines basic properties and compatibility requirements of the chosen liquids and substrates and makes recommendations for the dispensing.

For more information on our products and our range of services, follow this link or get in touch with us directly.

The Autodrop Gantry II system with all its features offers the user the possiblity to fully concentrate on their actual goal of researching and gaining knowledge about viruses and diseases, and reliably enables the entry into a production line in the further progression.

Contact us

Whether you're looking for solutions,

facing challenges or just want to let us know what your next project will be.

We are there for you.